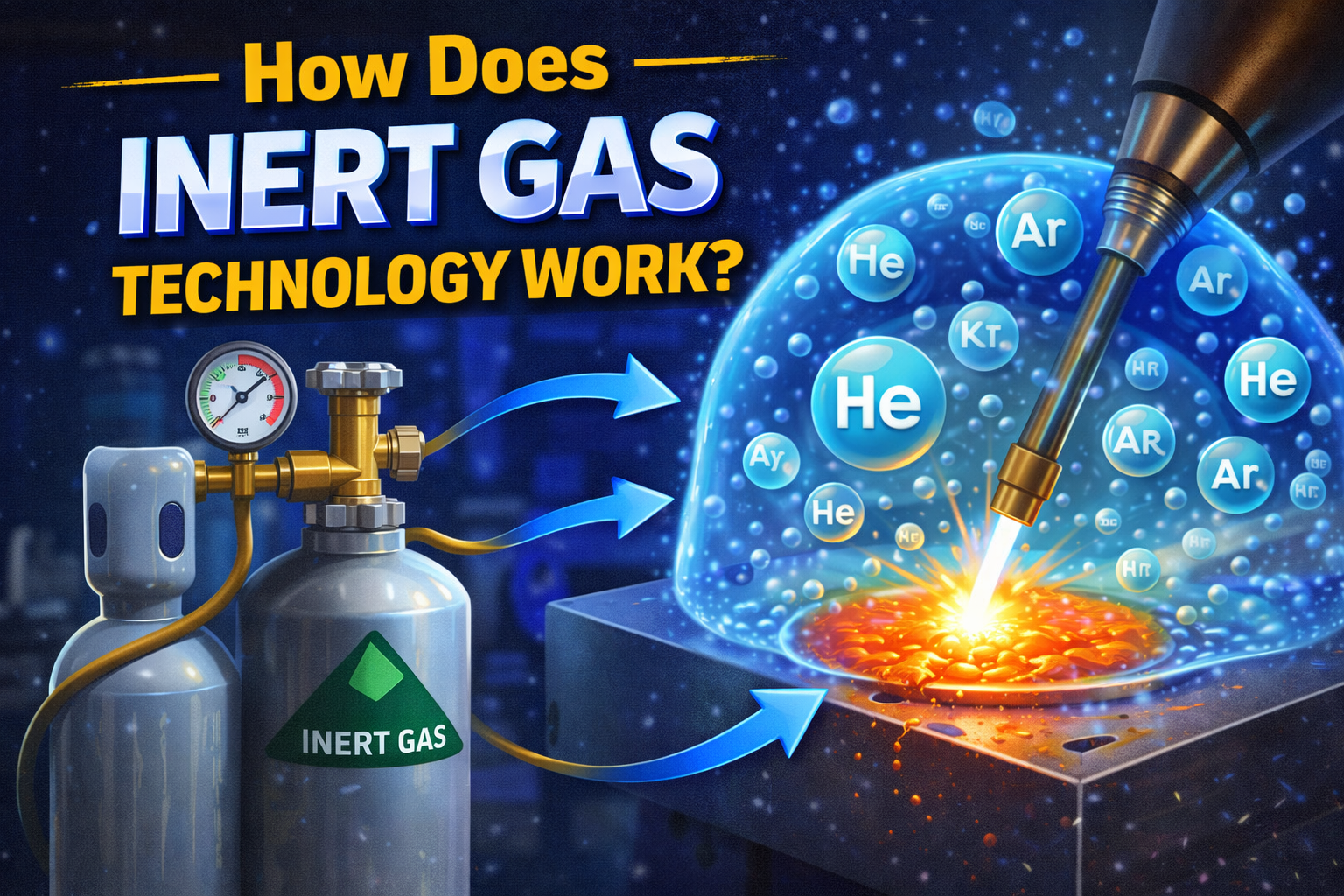

Imagine a world where oxidation, combustion, and spoilage are significantly reduced or even prevented. This isn’t science fiction; it’s the reality brought forth by inert gas technology. In an increasingly complex industrial landscape, understanding how does inert gas technology work is crucial for anyone involved in manufacturing, storage, fire safety, or even food preservation. This powerful approach leverages the unique properties of certain gases to create an environment that inhibits undesirable chemical reactions, offering a silent yet steadfast shield against damage and danger. By displacing reactive atmospheric oxygen, inert gases safeguard valuable assets, enhance process efficiency, and significantly improve safety across countless applications.

Key Takeaways

- Displacement of Oxygen: Inert gas technology primarily functions by replacing or diluting atmospheric oxygen, which is a key reactant in combustion, oxidation, and microbial growth.

- Non-Reactive Nature: Inert gases like nitrogen, argon, and carbon dioxide are chemically stable and do not readily react with other substances, making them ideal for protective atmospheres.

- Diverse Applications: From preventing explosions in chemical plants and preserving food freshness to protecting historical artifacts and enabling advanced welding, inert gas technology has widespread uses.

- Safety and Efficiency: Implementing inert gas systems enhances safety by reducing fire risks and improves industrial processes by preventing degradation and contamination.

- Environmental Considerations: While generally safe, the selection and management of inert gas systems also involve considerations for potential asphyxiation risks and efficient gas usage.

The Fundamentals of Inert Gas: What Makes a Gas “Inert”?

At its core, understanding how does inert gas technology work begins with the definition of “inert.” In chemistry, an inert substance is one that does not readily undergo chemical reactions. This non-reactive nature stems from the electron configuration of the atoms within the gas molecules. Specifically, gases like nitrogen ($text{N}_2$), argon ($text{Ar}$), helium ($text{He}$), neon ($text{Ne}$), krypton ($text{Kr}$), and xenon ($text{Xe}$) are considered inert or noble gases.

Why Non-Reactive?

- Full Valence Shells: Noble gases (argon, helium, etc.) have a full outer electron shell, making them extremely stable and unwilling to gain or lose electrons to form bonds.

- Strong Triple Bond: Nitrogen gas, while not a noble gas, is remarkably inert due to the very strong triple bond between its two nitrogen atoms ($text{N}equivtext{N}$). This bond requires a significant amount of energy to break, rendering it largely unreactive under most conditions.

This inherent stability is the cornerstone of their utility. When an inert gas replaces oxygen in an environment, it removes the primary ingredient necessary for many damaging processes.

The Mechanism: How Does Inert Gas Technology Work in Practice?

The practical application of inert gas technology hinges on the principle of oxygen displacement or oxygen dilution. Air, which surrounds us, is approximately 21% oxygen. Many undesirable reactions—like fires, explosions, and oxidation—require a certain concentration of oxygen to occur. By introducing an inert gas into an enclosed space, the oxygen concentration is lowered below the critical threshold, effectively suppressing these reactions.

Key Operational Principles

- Purging: This involves flushing a vessel or confined space with inert gas to remove existing atmospheric air (and thus oxygen) and replace it with a non-reactive atmosphere. This is common in chemical reactors and fuel tanks.

- Blanketing/Padding: A continuous, low-pressure flow of inert gas is maintained over the surface of a liquid or solid in a storage tank. This prevents air from entering and coming into contact with the product, protecting it from oxidation, moisture absorption, or evaporation.

- Inerting: Similar to purging, but often referring to creating a permanently inert atmosphere within a system to prevent ignition or chemical degradation.

- Fire Suppression: Inert gases are rapidly discharged into an area where a fire has started. By quickly reducing the oxygen level, the fire is extinguished without leaving behind harmful residues, unlike water or chemical suppressants.

Common Inert Gases and Their Roles

Each inert gas offers specific advantages depending on the application:

| Inert Gas | Key Properties | Primary Applications |

|---|---|---|

| Nitrogen ($text{N}_2$) | Abundant, cost-effective, slightly lighter than air | Purging, blanketing, fire suppression, food packaging, chemical processing |

| Argon ($text{Ar}$) | Denser than air, excellent insulator, very inert | Welding (TIG, MIG), specialized material processing, archaeology, high-purity environments |

| Carbon Dioxide ($text{CO}_2$) | Readily available, heavier than air, suffocating in high concentrations | Fire suppression, carbonation, some food preservation (less “inert” than N2/Ar but effective) |

| Helium ($text{He}$) | Very light, excellent thermal conductivity, non-flammable | Leak detection, cryogenics, specialized welding (for heat dissipation) |

“In essence, inert gas technology acts as a silent guardian, removing the very element that fuels decay and destruction, thereby extending the life and safety of countless products and processes.”

Applications Across Industries: Where Does Inert Gas Technology Shine?

The versatility of inert gas technology means it has permeated a vast array of industries. From safeguarding delicate electronics to preventing catastrophic explosions, its applications are both diverse and critical.

1. Fire Protection and Explosion Prevention

This is one of the most visible and critical applications. In environments with flammable liquids, gases, or dusts, even a small spark can lead to disaster. Inert gas systems are designed to prevent fires or extinguish them rapidly.

- Data Centers: Protecting valuable servers and data from fire without damaging electronics.

- Chemical Plants: Inerting storage tanks, reactors, and pipelines to prevent explosions of volatile substances.

- Oil & Gas Industry: Blanketing fuel tanks on ships (Inert Gas Systems – IGS), onshore storage facilities, and processing units.

- Archives & Museums: Protecting irreplaceable documents, artworks, and artifacts from fire without water damage.

2. Food and Beverage Preservation

How does inert gas technology work to keep your food fresh? Oxygen is a primary cause of food spoilage, leading to oxidation, discoloration, and microbial growth.

- Modified Atmosphere Packaging (MAP): Inert gases like nitrogen or argon are flushed into food packaging, displacing oxygen and significantly extending shelf life for products like meats, cheeses, and snacks.

- Wine and Beer Production: Preventing oxidation during fermentation, bottling, and storage maintains flavor and quality.

- Coffee Storage: Protecting roasted coffee beans from oxidation, which can quickly degrade flavor.

3. Manufacturing and Industrial Processes

Many industrial processes require an oxygen-free environment to ensure product quality and operational safety.

- Welding: Argon and helium are crucial shielding gases in welding to prevent atmospheric contamination (oxidation, nitriding) of the molten weld pool, resulting in stronger, cleaner welds. Learn more about understanding computer hardware components and functions where precise manufacturing is key.

- Chemical Manufacturing: Providing inert atmospheres for reactive chemicals, preventing unwanted side reactions or degradation during synthesis and storage.

- Electronics Manufacturing: Protecting sensitive components from oxidation during soldering, annealing, and storage.

- Pharmaceuticals: Maintaining sterile, oxygen-free environments for drug synthesis and packaging to prevent contamination and degradation.

4. Storage and Logistics

Protecting goods during storage and transit is another vital role for inert gas technology.

- Grain Storage: Preventing spoilage, insect infestations, and mold growth in large silos by creating an inert atmosphere.

- Historical Artifacts: Creating controlled environments to prevent degradation of delicate artifacts, textiles, and documents over long periods.

- Powder Handling: Preventing dust explosions in industries dealing with fine combustible powders (e.g., flour mills, pharmaceutical powder handling).

5. Research and Development

Scientific research often requires highly controlled environments.

- Glove Boxes: Scientists work with air-sensitive materials in sealed enclosures filled with inert gas, preventing reactions with oxygen or moisture.

- Material Science: Creating specific atmospheres for material synthesis, testing, and analysis.

Designing an Inert Gas System: Key Components and Considerations

Implementing an inert gas system requires careful planning and selection of components to ensure efficiency, safety, and effectiveness.

Core Components

- Inert Gas Source:

- Cylinders/Bundles: For smaller applications or specialized gases like argon/helium.

- Liquid Storage Tanks: Large bulk tanks for gases like liquid nitrogen or argon, which are then vaporized.

- On-site Generators: For nitrogen, pressure swing adsorption (PSA) or membrane separation units can produce nitrogen directly from ambient air, offering a cost-effective solution for continuous supply.

- Distribution System: Piping, valves, regulators, and flow meters to deliver the inert gas from the source to the point of use.

- Oxygen Sensors/Analyzers: Critical for monitoring oxygen levels in the inerted space, ensuring they remain below the desired threshold.

- Control System: Automation to manage gas flow, activate alarms, and potentially trigger emergency responses.

- Safety Measures: Pressure relief valves, ventilation systems, and personal safety monitors (for oxygen levels) are crucial, especially in confined spaces.

Design Considerations

- Gas Purity Requirements: Different applications demand varying levels of gas purity. Welding, for example, often requires very high purity argon.

- Flow Rate and Pressure: The system must deliver the correct flow rate and maintain the appropriate pressure to effectively displace oxygen without causing damage to the protected equipment.

- Volume of Space to be Inerted: This dictates the capacity of the inert gas source and the size of the distribution system.

- Temperature and Humidity: These factors can influence the effectiveness of inert gas and material compatibility.

- Cost-Effectiveness: Balancing upfront investment in equipment versus ongoing gas consumption costs. On-site generation can be a significant cost-saver over time.

- Safety Protocols: Comprehensive safety protocols are paramount due to the risk of asphyxiation in oxygen-depleted environments.

“Proper design and installation of inert gas systems are not just about efficiency; they are fundamentally about safeguarding lives and assets, reflecting a proactive approach to risk management.”

Safety Aspects of Inert Gas Technology

While incredibly beneficial, inert gas systems introduce unique safety considerations that must be diligently managed. The primary hazard is asphyxiation due to oxygen displacement.

Key Safety Measures

- Oxygen Depletion Monitoring: Continuous oxygen monitors with alarms are essential in areas where inert gas is used, especially in confined spaces.

- Ventilation: Adequate ventilation systems must be in place to purge inert gas from areas before human entry.

- Warning Signs: Clear signage indicating the presence of inert gas and potential oxygen-depleted atmospheres.

- Training: Personnel working with or near inert gas systems must be thoroughly trained on the risks, safety procedures, and emergency responses.

- Emergency Protocols: Established procedures for rescue and medical assistance in case of accidental exposure to an oxygen-deficient environment.

- Confined Space Entry Procedures: Strict adherence to confined space entry protocols when working in inerted vessels or rooms.

It’s crucial to remember that inert gases are odorless, colorless, and tasteless, making oxygen depletion undetectable by human senses. Relying solely on personal experience is dangerous; technological monitoring and strict safety protocols are indispensable.

Environmental Impact and Sustainability

As with any industrial process, the environmental footprint of inert gas technology is an important consideration, particularly in 2026 as global sustainability efforts intensify.

- Carbon Footprint: The production and transportation of inert gases, especially cryogenic liquids, consume energy and contribute to carbon emissions. On-site nitrogen generation can mitigate transport-related emissions.

- Greenhouse Gases: While gases like nitrogen and argon are not greenhouse gases, carbon dioxide, if used in large quantities and released, is a greenhouse gas. Systems using $text{CO}_2$ for fire suppression typically aim for rapid discharge to mitigate the fire, and the amount released is often small compared to industrial emissions.

- Resource Efficiency: Optimizing inert gas usage through efficient system design, leak detection, and recovery systems can reduce waste and environmental impact. For businesses looking to optimize processes, considering how AI can optimize business processes for maximum efficiency could also apply to managing inert gas systems.

- Responsible Sourcing: Ensuring that inert gases are sourced from suppliers committed to sustainable practices.

The Future of Inert Gas Technology in 2026 and Beyond

Looking ahead in 2026, inert gas technology continues to evolve, driven by advancements in efficiency, automation, and specific industrial needs.

- Smarter Systems: Integration with advanced sensors, AI, and IoT platforms will lead to more predictive maintenance, optimized gas usage, and enhanced safety monitoring. Imagine systems that can dynamically adjust gas flow based on real-time oxygen levels and process demands. For insights into how AI is shaping industries, explore how AI is transforming different business sectors.

- Miniaturization and Portability: Development of smaller, more efficient inert gas generators for niche applications or remote sites.

- New Gas Mixtures: Research into novel inert gas mixtures tailored for very specific reactions or materials, offering even more precise control.

- Closed-Loop Systems: Greater emphasis on gas recovery and recycling systems, especially for more expensive gases like argon and helium, to reduce operational costs and environmental impact.

- Emerging Industries: As new industries like advanced battery manufacturing, hydrogen storage, and sustainable aviation fuels develop, the demand for sophisticated inert gas solutions will only grow.

The core principle of how does inert gas technology work—oxygen displacement—will remain constant, but the methods and intelligence behind its application will become increasingly sophisticated, ensuring safer, more efficient, and more sustainable industrial operations for years to come.

Conclusion

Inert gas technology is an indispensable tool across modern industries, providing a silent yet powerful shield against the forces of oxidation, combustion, and degradation. By understanding how does inert gas technology work, we appreciate its fundamental role in safeguarding personnel, protecting valuable assets, ensuring product quality, and enhancing operational efficiency. From the simple act of keeping food fresh to preventing catastrophic industrial accidents, the controlled use of non-reactive gases like nitrogen and argon underpins countless processes that we often take for granted.

As industries continue to innovate and global safety standards become more stringent, the demand for sophisticated inert gas solutions will only grow. The ongoing integration of smart technologies, coupled with a persistent focus on safety and sustainability, ensures that this vital technology will continue to adapt and expand its protective reach. For businesses, investing in well-designed and properly managed inert gas systems is not merely a compliance measure but a strategic decision that offers tangible benefits in terms of safety, product integrity, and long-term operational resilience.

Actionable Next Steps

- Assess Your Needs: Evaluate your current operations for areas where oxygen exposure poses risks (e.g., fire, spoilage, material degradation).

- Consult Experts: Engage with inert gas system suppliers and safety consultants to design a system tailored to your specific requirements.

- Prioritize Safety Training: Implement comprehensive training programs for all personnel involved with or working near inert gas systems.

- Regular Maintenance: Establish a rigorous maintenance schedule for all components of the inert gas system, including sensors and safety devices.

- Explore On-site Generation: Investigate the feasibility of on-site nitrogen generators for long-term cost savings and reduced environmental impact.

Frequently Asked Questions about Inert Gas Technology

An inert gas is a gas that does not readily undergo chemical reactions with other substances. This non-reactive nature makes it ideal for creating protective atmospheres. Common inert gases include nitrogen, argon, and helium.

Inert gases prevent fires by displacing oxygen from an enclosed space. Fire needs oxygen to burn, so by reducing the oxygen concentration below a critical level (typically around 15% for most materials), the fire cannot ignite or is quickly extinguished.

Inert gas technology is used in various industries for fire protection, explosion prevention, food and beverage preservation (e.g., modified atmosphere packaging), welding, chemical manufacturing, electronics production, and the storage of sensitive materials.

When properly managed, inert gas technology is safe. However, the primary hazard is asphyxiation, as inert gases displace oxygen. Strict safety protocols, continuous oxygen monitoring, proper ventilation, and comprehensive training are essential to prevent accidents.

How to Design a Basic Inert Gas Purging System

Identify the Vessel or Space to be Purged

Determine the exact volume, shape, and access points of the vessel or confined space that needs to be inerted. This will help calculate the necessary gas flow and volume.

Select the Appropriate Inert Gas

Choose an inert gas (e.g., nitrogen, argon) based on your application’s requirements, cost, and product compatibility. Nitrogen is often the most common and cost-effective choice for general purging.

Determine Gas Source and Delivery Method

Decide if you will use high-pressure cylinders, a liquid storage tank, or an on-site nitrogen generator. Plan the piping, regulators, and flow meters needed to deliver the gas to your vessel.

Install Oxygen Monitoring and Safety Equipment

Integrate continuous oxygen sensors with alarms into the inerted space. Ensure proper ventilation, pressure relief valves, and clear warning signs are in place to prevent asphyxiation risks.

Develop and Implement Safety Protocols

Establish strict operating procedures, including confined space entry protocols if applicable, and provide thorough training for all personnel on system operation, hazards, and emergency response.

Key Terminology in Inert Gas Technology

Inerting

The process of rendering a space or vessel non-combustible or non-reactive by introducing an inert gas to reduce the oxygen concentration below the ignition threshold.

Purging

Flushing a vessel or pipe with an inert gas to remove undesirable gases, vapors, or liquids, often to eliminate oxygen or flammable atmospheres.

Blanketing/Padding

Maintaining a continuous, low-pressure layer of inert gas over the surface of a product (liquid or solid) in a storage tank or container to prevent contact with atmospheric air.

Oxygen Depletion

A reduction in the concentration of oxygen in an atmosphere, typically caused by the introduction of an inert gas, which can pose an asphyxiation hazard to humans.